Copyright © 2011-24 Helical Pile World, LLC. All Rights Reserved.

Home | Engineers | Manufacturers | Installation Contractors | News | Technical Advisors | Contact Us

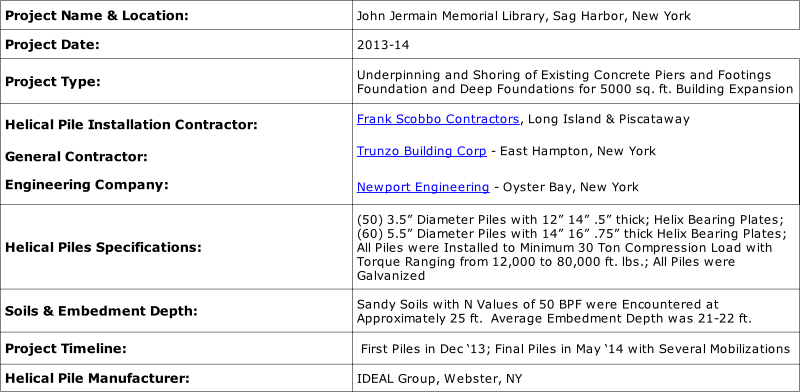

Scobbo Foundation Systems Installs (110) Helical Piles for Sag Harbor Historical Library Restoration and Expansion

Scobbo Foundation Systems

Division of Frank Scobbo Contractors, Inc.

Long Island, NY Piscataway, NJ

(516) 944-7154 (516) 944-PIER

Underpinning the Existing Structure

Underpinning the existing structure required that helical piles be installed on both the inside and outside of the existing walls and foundation.

Both 3.5” and 5.5” diameter helical piles were installed for the underpinning, which made the interior installations very challenging due to overhead restrictions combined with the necessity to have higher torque installation equipment inside the structure. 3 ft. and 5 ft. heilcal pile sections were used for the interior piles.

The helical piles for the underpinning and shoring were installed to a minimum capacity of 30 tons. Each underpinning pile and underpinning bracket were proof tested to 3 tons using calibrated hydraulic jacks. Once all underpinning piles were installed, the piles were loaded to 6 tons and were secured.

Project Overview

The John Jermain Memorial Library on Main Street in the Village of Sag Harbor is a (4) story structure originally built in 1910. The village decided to do some renovation work and add an additional 5000 sq. ft. of space to the back of this historic structure. The original foundation for this brick and limestone building consists of concrete piers and footings.

After the soils examination Frank Scobbo worked closely with Newport Engineering’s Chief Engineer, Nick DeSantis, on the design and installation plan for both the underpinning piles and the new deep foundation piles. Especially challenging was the installation of the interior piles due to low overheard and tight working quarters. Small installation equipment and 3’ and 5’ pile sections made the installation a slower and more tedious process. The foundation work was planned to take place in segments, and all of the piles were successfully installed from December ‘13 to May ‘14. The project is expected to be completed by the winder of 2014.

Excavating, Retaining Wall Construction and Helical Pile Installation

Scobbo Contractors was contracted to do all of the excavation work, install drilled casings, drive H piles, build the retaining wall and install the helical pile deep foundations.

Both 3.5” and 5.5” diameter helical piles were installed using mostly 20 ft. sections. The 3.5” piles had (2) helix bearing plates - 12” and 14” that were .5” thick. The 5.5” piles also had (2) helical bearing plates - 14” and 16” that were .75” thick. The helical piles were all hot dip galvanized and were manufactured by IDEAL Group.

Both vertical and batter piles were installed. There was (1) successful load test conducted on the 3.5” piles to 30 tons. The 5.5” piles were designed with a safety factor of (3), so no load tests were conducted. 12,000 and 80,000 ft. Lb. Torque motors were used to install the helical piles, and both digital and hydraulic torque indicators were used by the installers and the engineers for torque verification.

The majority of the piles were installed from December through March during the brutal northeast winter. The final piles were installed in early May, and the project is scheduled to be completed this coming winter.