Copyright © 2011-24 Helical Pile World, LLC. All Rights Reserved.

Home | Engineers | Manufacturers | Installation Contractors | News | Technical Advisors | Contact Us

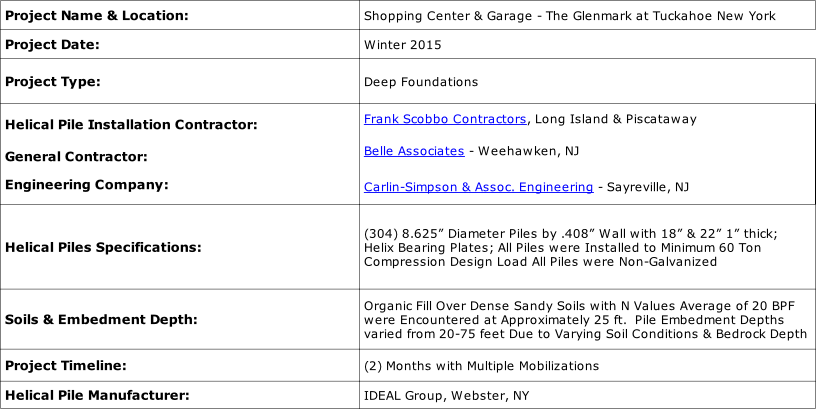

Scobbo Foundation Systems Installs (304) Large Diameter Helical Piles for Deep Foundations for a Major Shopping Center & Garage in Eastchester, NY

Scobbo Foundation Systems

Division of Frank Scobbo Contractors, Inc.

Long Island, NY Piscataway, NJ

(516) 944-7154 (516) 944-PIER

Project Overview

Originally, Torque Down Piles were specified for the project, however large diameter helical piles were proposed as an alternative due to improved production and cost savings. The engineering company, Carlin-Simpson & Associates Engineering, was not familiar with large diameter helical piles being used on sites with varying soil conditions, which was clearly the case on this site. Scobbo Foundation Systems executed load tests and performance tests per engineering specifications, and helical piles were approved for the project with a factor of safety of 2.2 for the design load of 60 tons on each pile. The biggest installation issues Scobbo faced was the varying soil conditions throughout the site with pile installation depths from 20 to 75 feet due to varying depths of fill, ground water levels and depth to bedrock.

Torque Down driven pipe piles were originally specified, but once the large diameter helical piles passed all performance tests and load tests to 60 tons design load, the helical piles were approved for the project as they were less expensive and faster to install.

The job site presented some challenges for the installation of the piles. There was a very large amount of debris in the fill that was documented from the soil borings. Debris such as ash, asphalt, brick, concrete, coal, and wood was noted within the fill at several of the boring locations. Where encountered in the borings, the existing fill extends to depths ranging from 1’6” to 14’6” below the existing ground surface. Scobbo’s installation crews were successful installing all of the helical piles right through all layers of debris. Additionally, bedrock depths across the site varied widely from 20 to 75 feet.

The (304) piles were installed during January and February with four mobilizations in spite of several snow storms and some very cold weather, which once again demonstrates the versatility of helical piles.

The 8.625” diameter by .408” wall with 18” and 22” helix bearing plates that were 1” thick were installed in 20 ft. and 25 ft. sections using a 80,000 ft. lb. torque motor. All sections were bolted together.